5 Good Reasons to Get Your Parts Coated!

Protection

Powder coating resists acid rain, many chemicals, the sun’s ultraviolet rays (fading) and road and weather damage (salt damage and chipping).

Superior Finish

When applied properly, powder coating does not run or drip, leaving the highest quality finish.

Environmentally Friendly

Powder coating eliminates most environmental concerns like VOCs during application and the need for costly waste disposal systems like conventional wet paint.

High Temperature Protection

Ceramic coatings are perfect for high temp applications (2000+ degrees) like mufflers, manifolds, headers, turbos and many other exhaust components.

A Restoration Must-Have

Performance car and antique car owners can powder coat suspension and chassis parts, engine parts and many other pieces for long term durability and fantastic looks.

What do we powder coat?

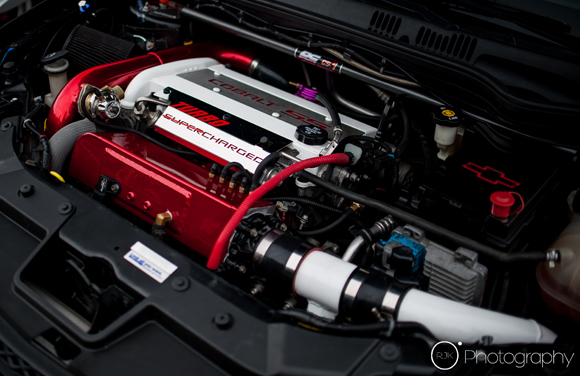

Ceramic coatings are typically used to control heat in car and motorcycle exhaust systems. The high temperature insulation offered by ceramic coating is an effective thermal barrier, controlling heat loss from car and motorbike exhaust systems and keeping exhaust and inlet manifolds cooler. Lower temperatures mean higher performance: it’s a no-brainer.

Most ceramic coatings are applied to car and motorbike exhaust systems, as high temp ceramic coating heat control technology is an excellent thermal barrier due to low heat conductivitity: ceramic coatings do not absorb heat as easily as metal. Racing teams and the military/defence industry pioneered the use of ceramic coating technology to reduce heat, and now car and motorbike owners have access to Performance Ceramic Coatings at a fraction of ceramic coating prices once charged for this proven performance enhancement.